-

2025-10-29

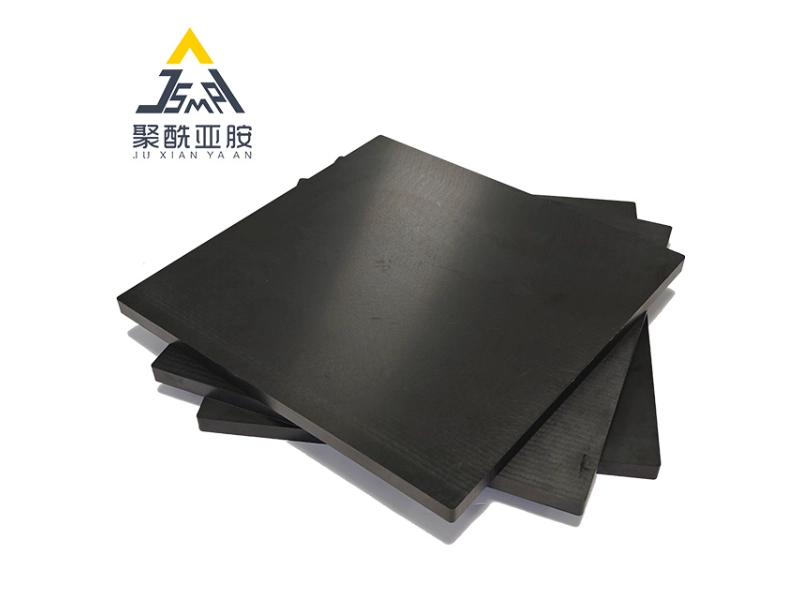

Reinforced Polyimide Composites: Strength and Reliability Combined

1. What Are Reinforced Polyimide Composites?2. Built for Extreme Temperatures3. Lightweight Strength That Lasts4. Resistance to Chemicals and Wear5. Applications Across Industries6. The Future of Reinforced Polyimides When it comes to materials that can handle extreme environments, reinforced polyimide composites are at the top of ...

view more

-

2025-10-13

How Polyimide Contributes to Lightweight Aerospace Components

1. What Makes Polyimide Special2. Lightweight Yet Durable3. Excellent Thermal and Electrical Insulation4. Resistance to Harsh Environments5. Paving the Way for Next-Generation AerospaceConclusion When it comes to building airplanes, satellites, and spacecraft, one of the biggest challenges is keeping everything as light as possible...

view more

-

2025-09-30

Exhibition Update | 2025 K Show in Germany | Huangshan Juxin Invites You to Join Us at the Rubber and Plastics Exhibition

1. Huangshan Juxin appeared at the K Show in Germany The 23rd International Plastics & Rubber Exhibition (K Show), the world's most influential event for the plastics and rubber industry, will grandly open at the Düsseldorf International Exhibition Center in Germany from October 8th to 15th, 2025! From Octobe...

view more

-

2025-09-27

Application Trends of Polyimide Materials in Plasma Cutting from an Environmental Perspective

1. Environmental Needs Driving New Material Adoption2. Green Performance Advantages of Polyimide3. Future Application Trends4. Conclusion In modern industrial manufacturing, plasma cutting technology is widely used in metal processing, machinery manufacturing, and construction due to its high efficiency and precision. However, with...

view more

-

2025-09-25

Comparison of Polyimide and Traditional Insulation Materials in Plasma Cutting Processes

1. Heat Resistance Comparison2. Electrical Insulation Comparison3. Mechanical Strength and Durability Comparison4. Overall Application Value In plasma cutting, the performance of insulation materials directly affects the stability and lifespan of the equipment. During cutting, high temperature, high pressure, and strong electric ar...

view more

-

2025-08-26

Polyimide vs. PTFE: Key Differences in High-Temperature Applications

1. Heat Resistance2. Mechanical Strength3. Chemical Resistance4. Electrical Properties5. Cost and Processing6. Conclusion When it comes to materials that can handle extreme conditions, polyimide and PTFE (Polytetrafluoroethylene, often known by the brand name Teflon) are two of the most widely used. Both are recognized for their du...

view more