-

2025-10-29

Reinforced Polyimide Composites: Strength and Reliability Combined

1. What Are Reinforced Polyimide Composites?2. Built for Extreme Temperatures3. Lightweight Strength That Lasts4. Resistance to Chemicals and Wear5. Applications Across Industries6. The Future of Reinforced Polyimides When it comes to materials that can handle extreme environments, reinforced polyimide composites are at the top of ...

view more

-

2025-10-13

How Polyimide Contributes to Lightweight Aerospace Components

1. What Makes Polyimide Special2. Lightweight Yet Durable3. Excellent Thermal and Electrical Insulation4. Resistance to Harsh Environments5. Paving the Way for Next-Generation AerospaceConclusion When it comes to building airplanes, satellites, and spacecraft, one of the biggest challenges is keeping everything as light as possible...

view more

-

2025-09-27

Application Trends of Polyimide Materials in Plasma Cutting from an Environmental Perspective

1. Environmental Needs Driving New Material Adoption2. Green Performance Advantages of Polyimide3. Future Application Trends4. Conclusion In modern industrial manufacturing, plasma cutting technology is widely used in metal processing, machinery manufacturing, and construction due to its high efficiency and precision. However, with...

view more

-

2025-09-25

Comparison of Polyimide and Traditional Insulation Materials in Plasma Cutting Processes

1. Heat Resistance Comparison2. Electrical Insulation Comparison3. Mechanical Strength and Durability Comparison4. Overall Application Value In plasma cutting, the performance of insulation materials directly affects the stability and lifespan of the equipment. During cutting, high temperature, high pressure, and strong electric ar...

view more

-

2025-08-26

Polyimide vs. PTFE: Key Differences in High-Temperature Applications

1. Heat Resistance2. Mechanical Strength3. Chemical Resistance4. Electrical Properties5. Cost and Processing6. Conclusion When it comes to materials that can handle extreme conditions, polyimide and PTFE (Polytetrafluoroethylene, often known by the brand name Teflon) are two of the most widely used. Both are recognized for their du...

view more

-

2025-08-14

Sustainable Polyimide Materials: Trends and Innovations

1. Eco-Friendly Manufacturing Processes2. Recyclable and Reusable Polyimide3. Bio-Based Polyimide Materials4. Energy Efficiency and Lightweight Applications5. Integration with Emerging Technologies6. Conclusion Polyimide is a high-performance polymer widely known for its excellent heat resistance, chemical stability, and electrical...

view more

-

2025-07-30

A brief understanding of the nine properties of polyimide (PI)

High-performance engineering plastic polyimide, is widely used in various fields due to its excellent thermal stability, mechanical strength, and electrical properties. With the advancement of technology, the application prospects of polyimide are becoming even broader, particularly in aerospace, electronics, and chemical industries, ...

view more

-

2025-07-15

Special Engineering Plastic Polyimide (PI): Supporting Performance Upgrades for Automotive Thrust Washers

In the thriving wave of the modern automotive industry, optimizing the performance of components has become a key issue in enhancing overall vehicle quality. Thrust washers, as crucial components in the automotive drivetrain system, directly impact the efficient and stable operation of vehicles. Special engineering plastic polyimide (...

view more

-

2025-06-27

Why Choose Polyimide Profiles Over Metals?

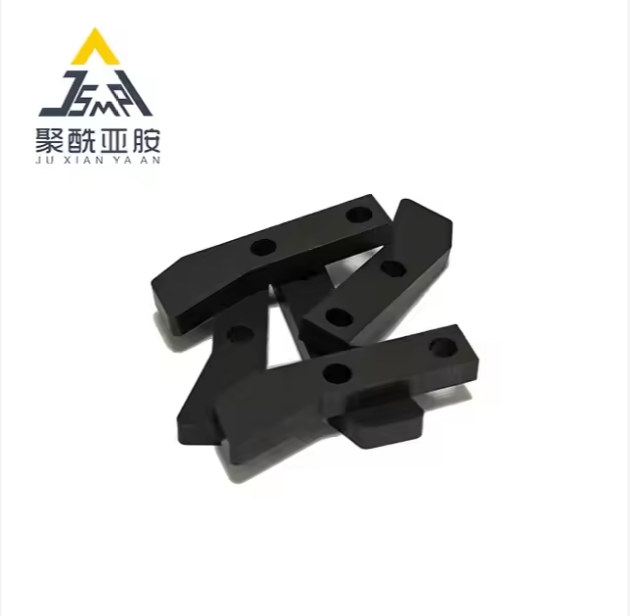

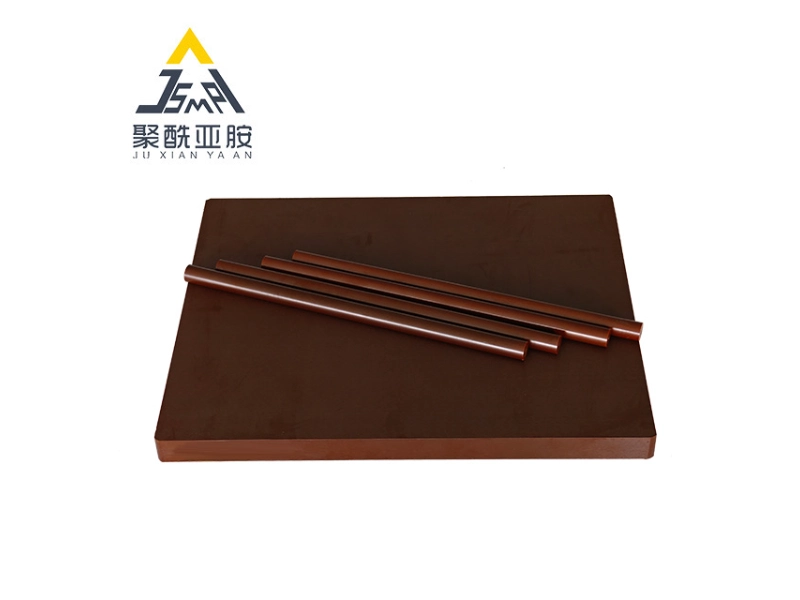

Polyimide (PI) profiles are like the high-tech plastic facing off against traditional metal materials. Below are some of the advantages of PI profiles explained in simpler terms: Lightweight but Strong: PI profiles are like lightweight boxers – they may be light, but they pack a punch. They are not as heavy as metals, yet their...

view more

-

2025-06-27

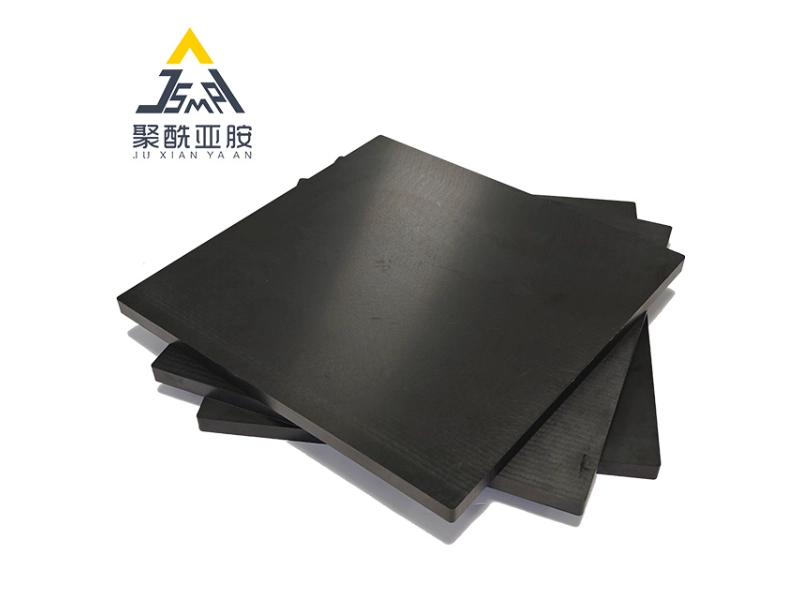

Key Role of Antistatic Polyimide Resin Sheets in Electronic Applications

As electronic devices continue to develop towards higher precision and performance, electrostatic discharge (ESD) has become one of the key factors affecting the reliability and performance of equipment. In semiconductor manufacturing, microelectronics engineering, and precision instrument applications, electrostatic discharge can cau...

view more

-

2025-06-13

The Innovative Application of Polyimide in Automotive Engine Systems: Driving Breakthroughs in Power and Efficiency

As automotive technology continues to evolve, the dual pressures of enhancing engine performance and meeting environmental standards make material innovation crucial. Polyimide, a high-performance plastic, has shown tremendous potential in automotive engine systems due to its exceptional heat resistance, mechanical strength, and elect...

view more

-

2025-05-16

Selection of Ultra-Wear-Resistant Materials: Advantages and Challenges of Polyimide

In modern industry, wear resistance is a crucial factor for the success of many applications, especially in environments that require long-term, high-load operations. Choosing the right ultra-wear-resistant material is key. Polyimide (PI), as a high-performance engineering plastic, has become one of the preferred materials in many hig...

view more