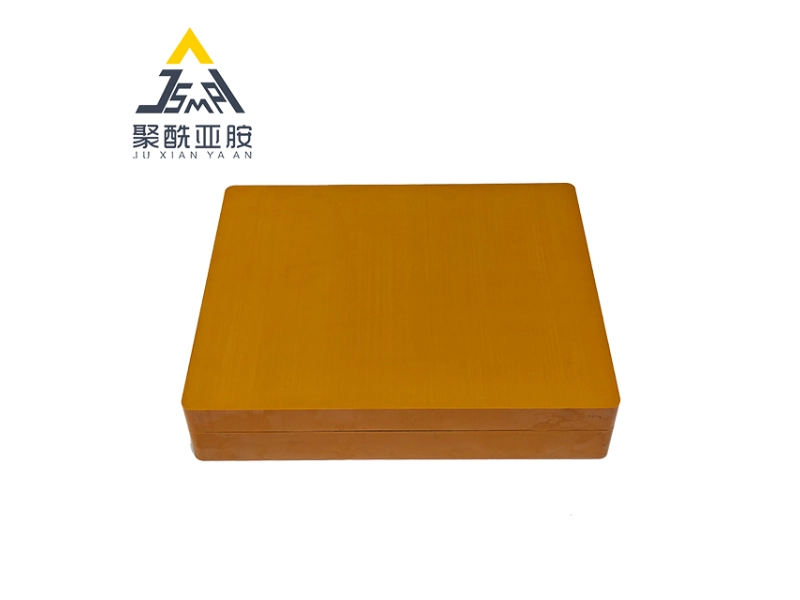

As electronic devices continue to develop towards higher precision and performance, electrostatic discharge (ESD) has become one of the key factors affecting the reliability and performance of equipment. In semiconductor manufacturing, microelectronics engineering, and precision instrument applications, electrostatic discharge can cause damage to components, data loss, or system failures, thereby affecting the overall stability and lifespan of the equipment. To address this issue, antistatic polyimide resin sheets, as a new material, have become an important protective material in the electronics industry due to their excellent antistatic properties, electrical insulation, and resistance to high temperatures and corrosion. This article will focus on the key role and advantages of antistatic polyimide resin sheets in electronic applications.

1. Outstanding Antistatic Performance

Antistatic polyimide resin sheets can effectively suppress static charge accumulation and prevent electrostatic discharge (ESD) from damaging electronic devices and components. By incorporating antistatic additives or using special processing techniques, these sheets control the release of static charges, ensuring the safety of electronic products during production, transportation, and storage. In sensitive electronic components and microelectronic devices, they significantly reduce the failure rate caused by electrostatic discharge, improving product reliability.

2. Excellent Electrical Insulation

Another major advantage of polyimide resin sheets is their excellent electrical insulation performance. In electronic devices, electrical insulation is crucial, especially in high-frequency circuits and high-voltage applications, to prevent accidental conduction between components. Anti static plastic polyimide sheet provide stable electrical isolation, preventing short circuits, current leakage, and other issues, thereby enhancing the safety of the equipment.

3. High Temperature and Environmental Resistance

Electronic devices are often exposed to high temperatures and harsh environments during operation, especially in industrial applications and high-power equipment. Antistatic polyimide resin sheets have excellent high-temperature resistance, capable of withstanding extreme temperature variations without deformation or performance degradation. In addition, they are resistant to chemical corrosion, able to withstand the erosion of acids, alkalis, and solvents, ensuring the long-term stable use of equipment in various harsh environments.

4. Mechanical Strength and Durability

The mechanical protection provided by polyimide resin sheets is also critical for the long-term use of electronic devices. They possess high mechanical strength and wear resistance, effectively preventing damage caused by external forces. This material offers significant advantages in protecting sensitive electronic components from external impacts, vibrations, or friction, making it especially suitable for high-strength work environments where equipment protection is essential.

5. Good Processability

Antistatic polyimide resin sheets have good processability, allowing them to be cut, formed, or processed according to the specific needs of different electronic devices. Whether for small customized components or large protective layers, polyimide resin sheets can flexibly adapt to meet the requirements of different shapes and sizes. This makes them highly versatile in electronic device design and manufacturing, providing precise static protection for various complex structures.

6. Environmental Friendliness and Safety

As global environmental standards become increasingly stringent, the electronics industry is also placing higher demands on the environmental friendliness of materials. Antistatic polyimide resin sheets, as an eco-friendly material, have a low environmental impact during production, use, and disposal, making them a green choice. They do not contain harmful substances, will not release toxic gases during use, and comply with international environmental standards, ensuring the safety of both the environment and operators.

Antistatic polyimide resin sheets, with their outstanding static protection, electrical insulation, high-temperature resistance, chemical corrosion resistance, and excellent mechanical properties, play an important role in the electronics industry. They not only effectively address the potential hazards of electrostatic discharge on electronic devices but also provide long-lasting protection for high-precision electronic products. As electronic technology continues to advance and application demands increase, the widespread use of antistatic polyimide resin sheets will further promote innovation in the electronics industry, becoming a core material to ensure equipment stability and enhance product quality.